Chemical name: Urea

CAS No.: 57-13-6

Formula: CH4n2o

EINECS: 200-315-5

Certification: ISO9001, TUV, GMP, ISO, CE

Application: Vegetables, Flowers, Fruit

Appearance: Granular

Equivalent Product Name: N.A

Equivalent Chemical Name:diamino methanal;Urea; UREUM;

Customization: Available

Description

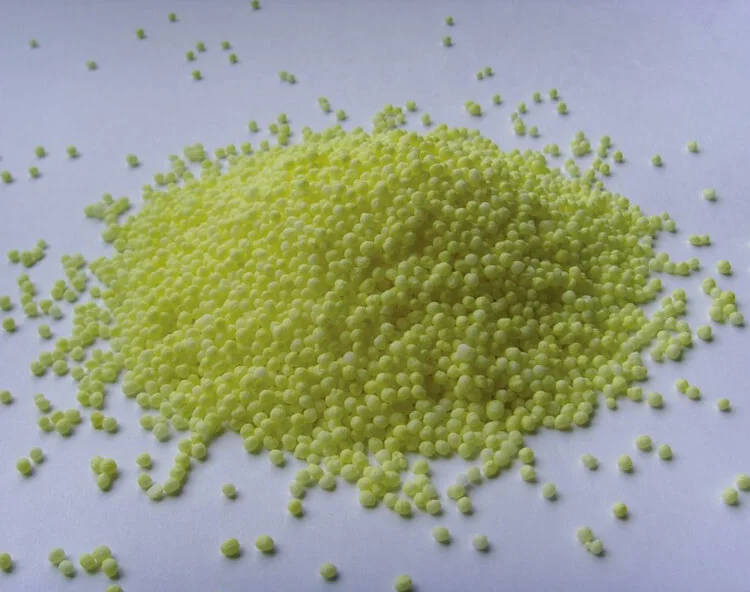

Sulfur Coated Urea Scu, Sulfur as the main wrapping material, wrapped urea, to achieve slow release of nitrogen fertilizer, also known as sulfur-coated urea. The wrapping material has sulfur or microcrystalline wax, according to the different coating materials, it can be divided into sulfur-coated controlled-release fertilizer resin-coated controlled-release fertilizer, and other fertilizers.

Sulfur-coated urea has a unique color, and belongs to the inorganic coating type of slow-release fertilizer, urea or compound fertilizer surface has a layer of film, the unique sulfur composition, can control the rate of nutrient release, nutrient release is continuous and stable, suitable for a variety of soils and crops, to meet the nutritional needs of the crops due to the seasons, to improve the quality and increase yields. Urea or compound fertilizer has a film on the surface, a unique sulfur composition, which can control the rate of nutrient release.

Sulfur-Coated Urea Specifications

| Name | Sulfur Coated Urea | Class | AAA | ||

| Mark | / | Department | Quality Control Department | ||

| Sample Base | 200 MT | Sample Size | 500g | ||

| Batch No | 2022060610 | Sampling Personnel | DICKE, CHEN | ||

| Sampling Date | 5th Aug 2022 | Test Date | 5th Aug 2022 | ||

| Inspection basis | GB29401-2012 Sulfur Coated Urea(SCU) | ||||

| NO. | ITEMS | SPECIFICATION | RESULT | RESULT | |

| 1 | N % | ≥37.0 | 37.6 | QUALIFIED | |

| 2 | INITIAL NUTRIENT RELEASE RATE % |

≤27.0 | 22.6 | QUALIFIED | |

| 3 | STATIC NITROGEN DEDUCTION RATE | ≤45.0 | 38.5 | QUALIFIED | |

| 4 | MOISTURE(H2O) % | ≤1.0 | 0.8 | QUALIFIED | |

| 5 | BIURET % | ≤1.2 | 0.4 | QUALIFIED | |

| 6 | S % | ≥10.0 | 10.5 | QUALIFIED | |

| 7 | SIZE(2.00~4.75mm) % | ≥90 | 95 | QUALIFIED | |

| REMARK | TOTAL N ≥37.0% | ||||